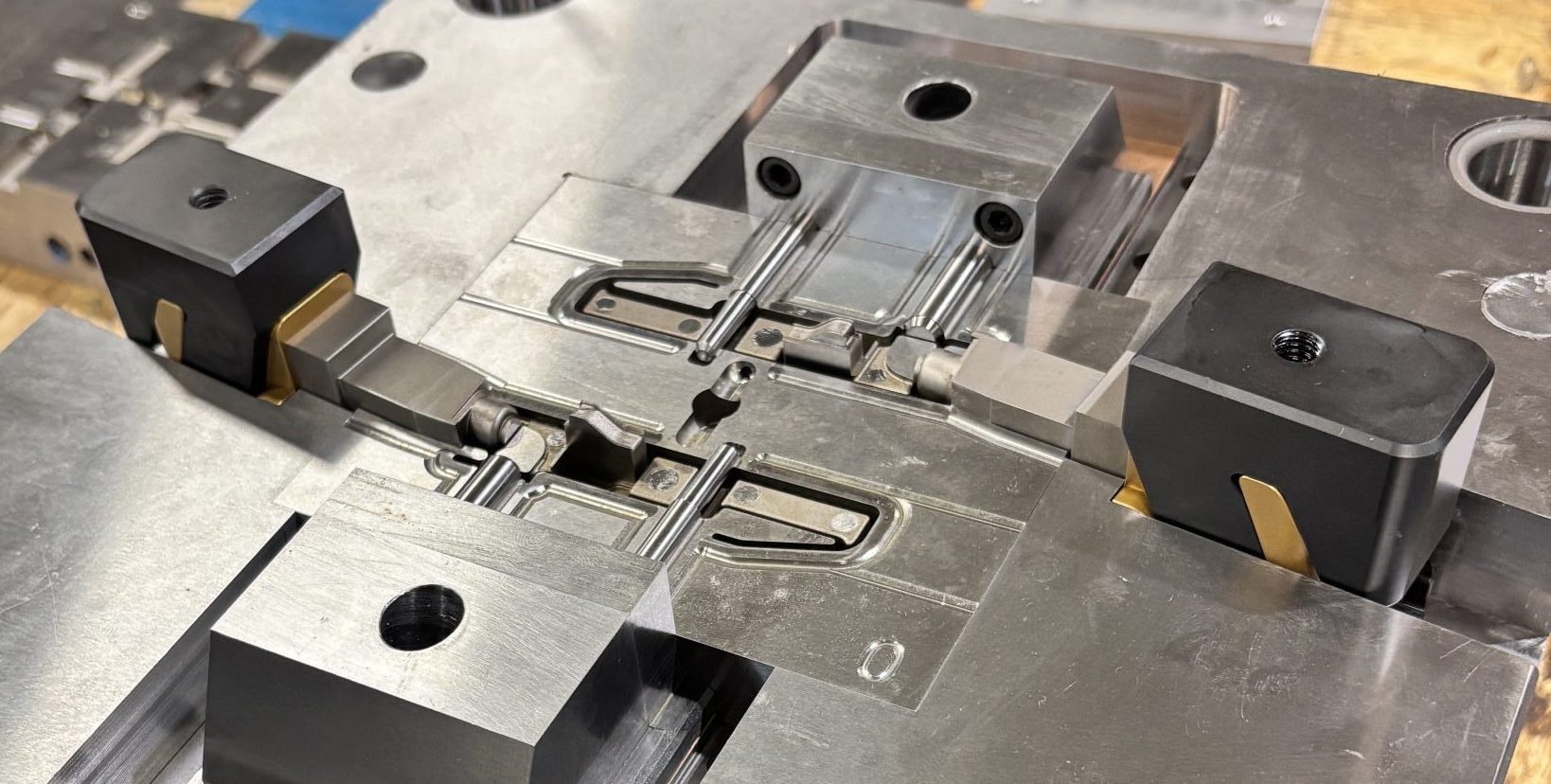

Molds & Tools

We can create a variety of quality molds, including the design, prototype, and production. Our team can take you from rough sketches all the way to a production-ready mold.

About Prairie Tool Co.

Founded in 1989, Prairie Tool Company is a trusted leader in plastic injection molding solutions. We’ve grown steadily over the years, expanding twice to reach our current footprint of 12,000 square feet. Our focus is delivering fast, innovative, and precise solutions for all your plastic injection molding needs, including high-quality molds, custom mold tooling, and specialized fixturing.

By equipping our experienced designers with the latest CAD/CAM software and investing in advanced high-speed machining and EDM technology, we consistently produce molds with exceptional precision and quality. This combination of expertise and technology allows us to offer some of the shortest lead times in the industry, helping our customers bring products to market faster and more efficiently.

Our Capabilities

At Prairie Tool Company, we specialize in guiding customers through the entire plastic injection molding process—from rough concept to final design to fully completed tooling ready for production. Our team is known for quick-turnaround delivery on prototype molded parts, helping you accelerate product development timelines without sacrificing quality.

With extensive experience across a wide range of industries—including medical, consumer products, lawn and garden, agriculture, electrical, and appliances—we’re equipped to handle complex projects with precision. By combining expert design support with advanced mold tooling, fixturing, high-speed machining, and EDM technology, we deliver high-quality molds tailored to meet the exact needs of each application.

Plastic Part Design

Drawing from our years of experience in the mold making industry, we are able to convert your ideas, sketches, or drawings into 3D designs suitable for molding. A good part design can provide returns in lower tooling costs, lower costs per piece, and a higher quality end product.

Molds

We mainly produce steel molds and are familiar with the special needs required to make any specialty mold. The complex geometry and tight tolerances combined with the need to eliminate flash along parting lines creates some of the greatest challenges to us as mold builders.

Mold Design

Drawing from our years of experience in the plastics field, we are able to convert your ideas, sketches, or drawings into 3D designs suitable for molding. A good part design can provide returns in lower tooling costs, lower costs per piece, and a higher quality end product.

Production Molds

We manufacture production molds for a wide range of industries, including medical, electronics, small engine, and consumer products. Our capabilities include all mold types, MUD inserts, self-contained, three-plate, and stripper plate, in materials such as P20, S7, H13, stainless steel, MoldMAX, aluminum, and Ampco. We offer multiple gating methods to meet customer needs, including tab, tunnel, hot sprue bushing, valve gate, and multi-drop hot manifolds. Our experience includes multi-cavity, family molds, unscrewing molds, interchangeable cores/cavities, and multi-top or bottom half designs. Every project is approached with a focus on delivering the best quality and value through tailored solutions that match the unique application requirements of each customer.

Prototype Molds

We provide prototype molds for customers at their request. Materials for mold construction are either steel or aluminum. Because of the unique nature of prototype molds, the delivery, design, and any special functions or limitations are outlined at the beginning of the project.

Production Assembly

We provide value-added services designed to streamline your manufacturing processes and reduce overall costs, empowering you to achieve greater efficiency and quality.

Graphite Electrode Machining

We provide custom graphite electrode design and milling. We use either Surfcam or WorkNC to calculate tool paths from the CAD data supplied by the customer. The electrodes are then cut on either our two graphite mills. Both graphite mills are setup to handle both the 3R Macro system for pallets and the 3R Micro system with 20mm stems. Graphite choice is based upon the application or customer request.

Custom Machining

We provide value-added services designed to streamline your manufacturing processes and reduce overall costs, empowering you to achieve greater efficiency and quality.We also offer custom machining on an hourly or job basis. We are able to offer 4 axis wire EDM, plunge (sinker) EDM, and high speed machining services. Our lineup or Makino, OKK, GE Fanuc, and Hurco equipment is sized to handle almost any job large or small.

“We’ve worked with Prairie Tool for many years on countless projects, and their commitment to delivering high-quality molds has been outstanding. Their team consistently meets our needs, and we appreciate their collaborative approach to helping us move into production efficiently. We highly recommend them to anyone looking for a trusted manufacturing partner.”

Valued Customer

Our Equipment

Here is a list of equimpment we have available at our facility.

Manual Equipment

- 1996Roll-In Saw

- 1998Marvel Series 8 Mark III Band Saw

- Kerney & Trecker Milwaukee Model 550 Milling Machine

- 1974Bridgeport Milling Machine Series II

- 2003Sharp QMV-1 Vertical Turret Milling Machine

- 1993Acer Ultima-3VK Vertical Milling Machine

- Cincinnati TM-407 Horizontal Milling Machine

- OOYA Radial Arm Drill

- 1980Drillmation 1100 Gun Drill

- 1979K.O. Lee B6060 ID/OD Grinder

- 1994Chevalier Grinder FSG-1632

- 1975Brown & Sharpe Surface Grinder

- 1977Brown & Sharpe Surface Grinder

- 1990Kent KGS-620 AHD 24×80 Surface Grinder

- 1989Kuhlman Tool & Cutter Grinder

- 1999Chevalier Surface Grinder Accugrind 618SP

- 1998Rocklin Mold Mender Micro Welder Model 912

- 1992Miller Dynasty 200 Tig Welder

- 1992Miller Coolmate 3 Wire Welder

- 2010Powercut 900 Plasma Cutter ESAB

- 2010Millermatic 350P Welder

- 1998Toyota Forklift

Building

- 9855 sq. feet of work space

CNC Equipment

- 2002OKK VM5-II W/Mitsubishi 635 Controls

- 2003Hurco VMX 64/50

- 1997Hurco BMC 50/50 (background)

- 2002Hurco VMX 40 (foreground)

- 2000Okada GMC 654 W/Fanuc Controls

- 1996Romi Bridgeport EZ Path II 20/10 Lathef

- 1995Brown & Sharpe Microval CMM

- 1999OKK MCV-1060 W/Mitsubishi 635 Controls

EDM Equipment

- 1997Makino Sinker Model EDNC-65 (background)

- 1998Makino Sinker Model EDNC-43S (foreground)

- 2001Makino EDGE2 RAM EDM Machine

- 2007Makino SP64 Precision Wire EDM Machine

- 1997Fanuc Robocut Wire EDM

- 2005Mitsubishi ED-2000M EDM Drill (Hole Popper)

- 1990Westoff Electrode Drilling Machine

Computer Software

- Pro-E Wild Fire 5.0

- Solid Works

- Surfcam Velocity

- Work NC

Get Started!

Contact us now for fast, innovative solutions to your molding and manufacturing needs!

© 2025 Prairie Tool Company. All Rights Reserved | Web Development by McQuillen Creative Group